Improvement programs must be:

- Measurable: quantify original capabilities, identify defects,

and set objectives - Predictive: statistical models predict output improvement

when objectives are achieved

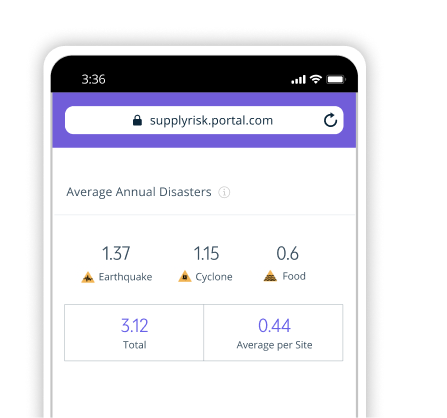

SRS identified a specific set of Key Risk Predictors™ (KRP) of production disruptions. Suppliers with high KRP scores are 500% more likely to suffer production disruptions than better prepared peers in the same area.